A Sandwich Belt conveyor uses two conveyor belts, face-to-face, to gently but firmly contain the product being carried, hence making steep incline and even vertical-lift runs easily achievable.

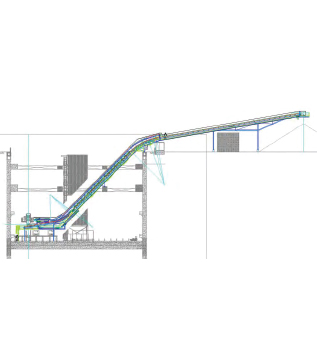

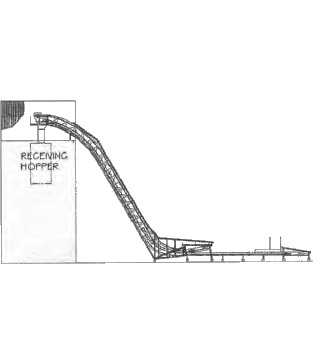

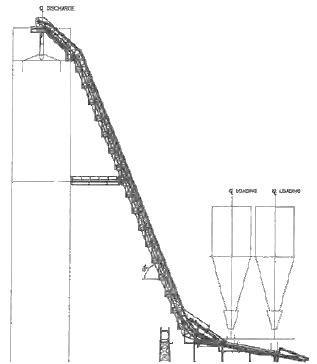

A Sandwich Belt conveyor uses two conveyor belts, face-to-face, to gently but firmly contain the product being carried, hence making steep incline and even vertical lift runs easily achievable. Sandwich belt high angle conveyors are available in widely ranging profiles of C and S-shape. In either case, a long bottom belt approach is possible to the Sandwich entrance, and the discharge may be on the high incline or after the extension of the carrying belt beyond the mouth of the Sandwich.

With hundreds of applications around the world, you can find Sandwich Belt high angleconveyors in the following applications:

Sandwich Conveyor for Copper Mine, Eastern Europe

DS 003

Sandwich Conveyor for Metro Project, Los Angeles, CA, USA

DS

005

Sandwich Conveyor for Coal Prep Plant, Eastern USA

DS 009

Sandwich Conveyor for Coal Mine, Western USA

DS 011

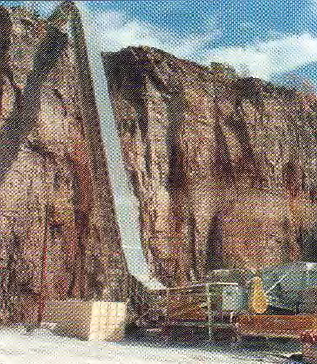

Downhill Sandwich Conveyor from Phosphate Mine, Venezuela

DS

021

Sandwich Conveyor at Underground Gypsum Mine, Eastern USA

DS

024

Sandwich Conveyors Units 061 & 062 for Cement Plant, Indonesia

DS 061

Sandwich Conveyor for Limestone Quarry, Midwest USA

DS 064

Sandwich Conveyor for Steel Mill, Southern USA

DS 080

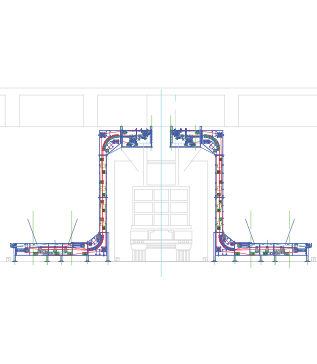

Two-Units EleVeyor EL for Blue Plains -WWTP (Data, Each

Unit)

DS 083

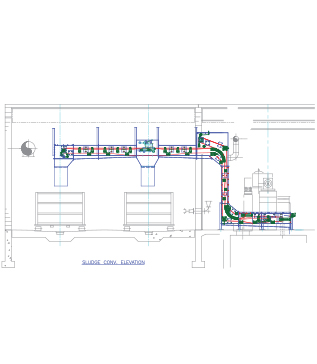

EleVeyor EL for Foxwood Casino -WWTP

DS 085

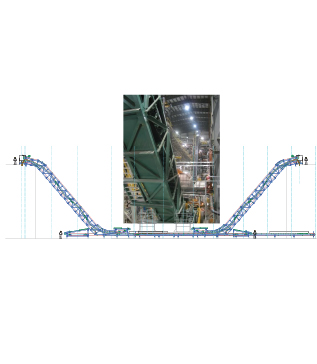

DSI Snake #2 Sandwich Conveyor for Continental CN at Snap Lake

Diamond Mine (Initial / Future)

DS 092

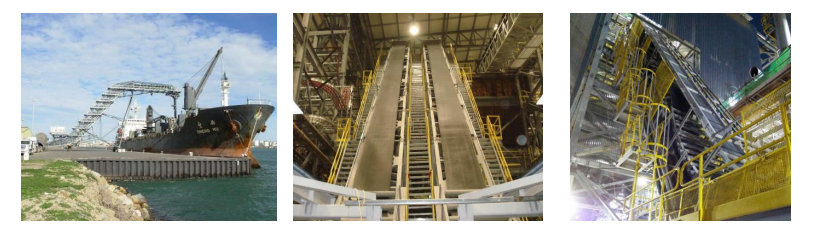

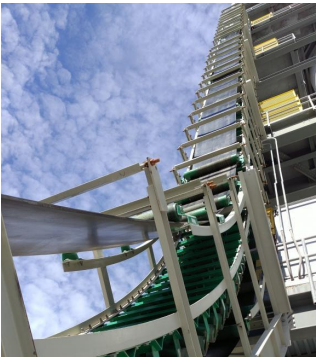

DSI Snake Sandwich Conveyor Shiploader for Cortex Resources at

Port Adelaide, Australia

DS 097

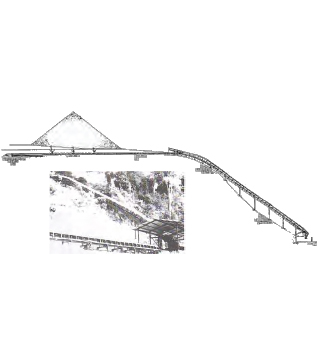

DSI Snake Sandwich Conveyor for Oxbow, Ltd, Fawley Plant,

Southampton, UK

DS 103

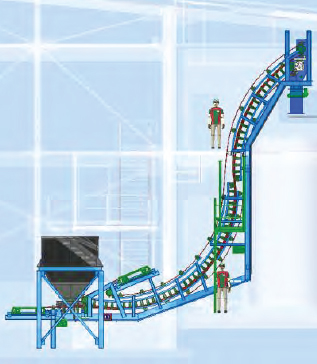

DSI Sandwich Conveyor for SNF Coagulants, St. Avold France

DS

115

DSI Sandwich Conveyor for Singapore Airport

DS 116