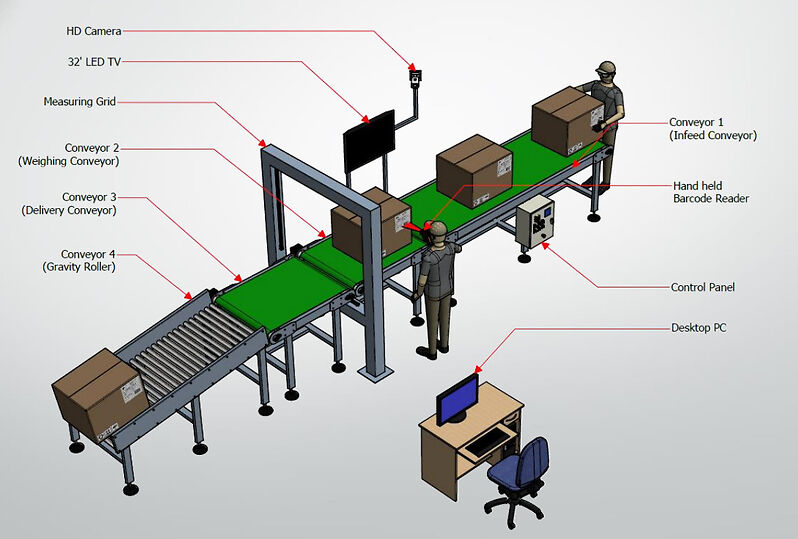

Dimension & Weighing Measurement System are designed on keeping into account the prevalent shipment size and weights in the Industry so that clients can leverage on a standard plug and play system that offers them high accuracy, reliability, uptime and productivity.

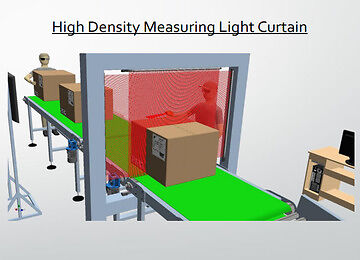

Our System facilitate accurate capturing of a Product’s Dimensions (Length, Breadth, Height, Actual Volume) and Actual weight against the product identifier (usually a barcode) and store this information in Databases.

| Dimension & Weighing Measurement System Specifications | |

|---|---|

| Maximum Parcel Size | 900mm X 900mm X 900mm |

| Max Weighing Capacity | 75kg |

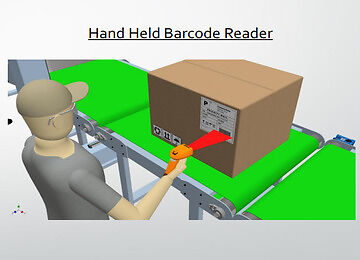

| Readable Barcode type | 1D |

| Barcode Scanner | Handheld Barcode Scanner |

| Line Speed | 3mtr/sec (adjustable) |

| Weighing Accuracy error | 0.1% |

| Dimension Accuracy Error | W:5mm X H:5mm X L:2mm |

| Additional Features | Uploading/inserting of processed data to SAP/DATABASE |

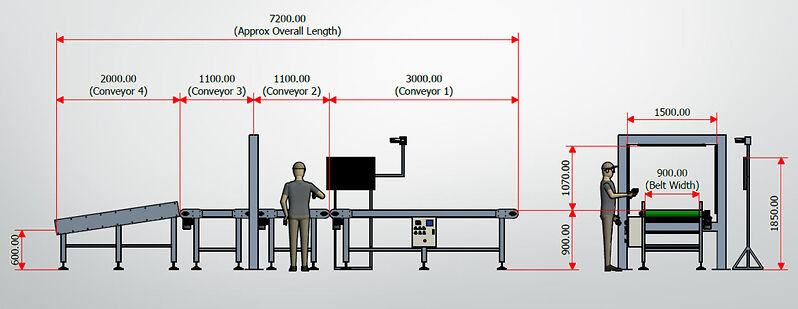

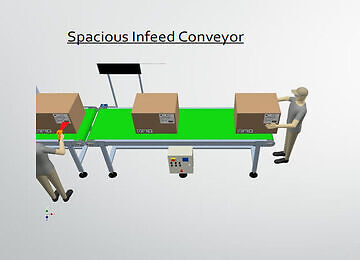

| Infeed Conveyor Size | (L: 3000mm X W: 1000mm X H: 900mm) Belt Width:900mm |

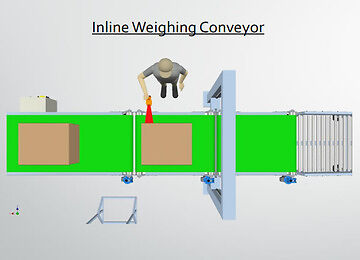

| Weighing Conveyor Size | (L: 1100mm X W: 1000mm X H: 900mm) Belt Width:900mm |

| Delivery Conveyor Size | (L: 1100mm X W: 1000mm X H: 900mm) Belt Width:900mm |

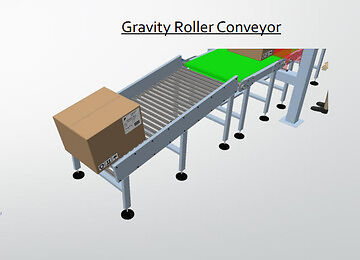

| Inclined Gravity Roller Conveyor | (L: 2000mm X W: 1000mm X H: 900mm to H:600) |

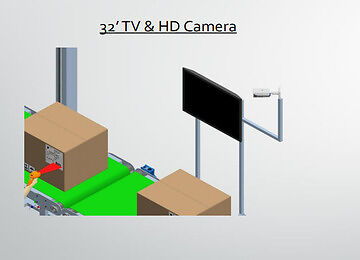

| Camera | HD IP Camera |